Jewelry Polishing Industry

Why Choose Yen Shen for the Jewelry Polishing Industry?

In the application of jewelry polishing machines, Yen Shen Electric is a trusted partner that helps clients gain a competitive edge. As the market demands unique applications and enhanced processing capabilities, Yen Shen focuses on the R&D and design of customized motors, delivering high-performance solutions to effectively address issues like unstable speeds, overheating, and high maintenance costs.

Challenges & Solutions

Success Stories

Clients using our customized motors have significantly improved processing efficiency and product quality. Polishing time was reduced by 30%, and product pass rates increased to 95%

Data Highlights

Processing precision improved

Failure rates reduced

Comprehensive Solutions

In addition to providing high-efficiency motors, we optimize overall mechanical design to reduce wear on other components and enhance system efficiency.

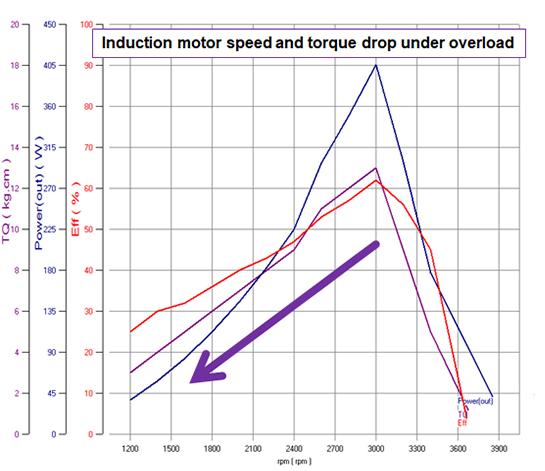

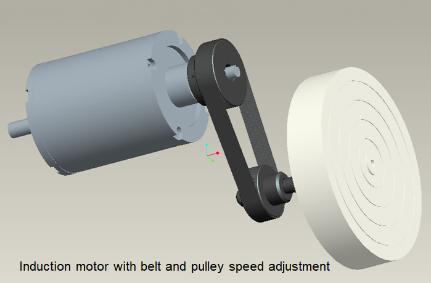

Traditional polishing machines typically use induction motors with belt pulleys to drive wheels or belts. However, under rough grinding conditions, belt pulleys are prone to slippage or severe wear, leading to unstable speeds due to drastic load changes. This results in excessive material consumption or uneven surfaces. From the TN curve of induction motors, it is evident that during heavy loads, speed decreases while torque simultaneously diminishes. This forces technicians to constantly adjust their force according to speed changes, affecting process stability and making it challenging to standardize operations and establish an efficient SOP.

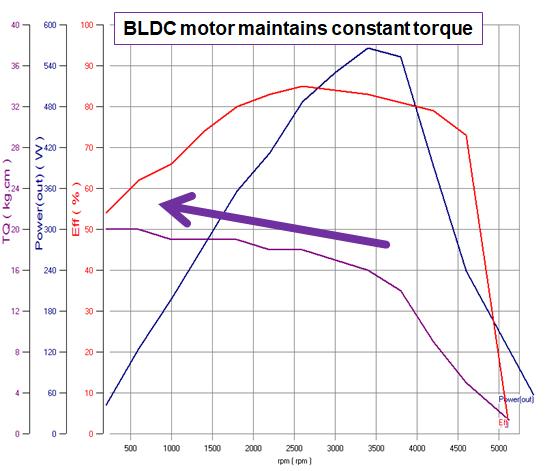

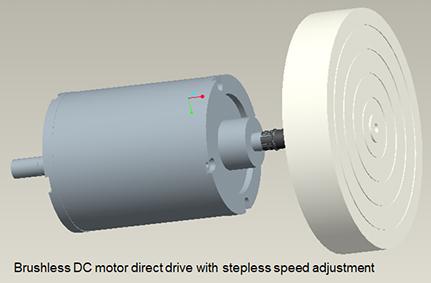

To address these issues, we use brushless DC motors (BLDC) to directly drive wheels and belts, eliminating instability caused by belt pulleys while avoiding the hassle of belt wear and replacement. With the load-speed feedback control mechanism of BLDC motor controllers, speeds remain stable even under heavy loads, maintaining nearly constant torque. This ensures stable processing conditions, reducing reliance on technicians’ experience. As a result, machine operational stability improves significantly, helping to establish standardized SOPs and minimize operator-induced material wastage.

Moreover, with stable mechanical performance, semi-automated production can be further introduced, significantly enhancing output. This transforms the traditional diamond polishing industry from labor-intensive to technology-driven, reducing personnel management uncertainties and effectively lowering labor costs, laying the foundation for industry upgrades.

Technical Support & Training

We provide comprehensive technical support and training to ensure clients maximize the potential of our products.